Asset Performance Management (APM) is a series of software and services designed to help optimize equipment reliability and O&M efficiency across the plant and the entire fleet. Featuring Digital Twin analytics, work process automation, and built-in GE expertise, APM is the backbone of modern power generation operations.

APM’s rich functional pillars for Health, Reliability, and Asset & Maintenance Optimization are available both as a cloud-based service on the Predix Platform as well as on-premises software.

SPE serves more than 10 million customers in Algeria. Their investments in remote monitoring and commitment to digital transformation have led to best-in-class maintenance cost management.

Currently, GE Digital monitors three of SPE’s power plants from a Monitoring and Diagnostics (M&D) center in the capital city of Algiers, using Asset Performance Management (APM) and Operations Performance Management (OPM) software.

Watch Sabri Lezhari, CEO of SPE, as he walks through the company's digitization journey. This presentation is in French with English subtitles.

Reduce unplanned downtime and increase availability and reliability by helping to ensure critical assets and systems are monitored and protected from emerging threats.

Improve workforce productivity by prioritizing maintenance based on criticality and cost (condition-based) rather than schedule-based maintenance practices.

Protect the health and safety of employees, the environment, and business objectives, by reducing asset-related incidents and unplanned downtime.

Reduce costly emergency repairs by detecting problems early, turning unplanned downtime into planned/scheduled downtime.

Reduce TCO delivered via a Software-as-a-Service (SaaS) model, providing flexibility and access to business insights where it matters—with the edge, cloud, and hybrid configurations.

A standardized way to connect machines, data, and people with a consistent interface for superior user experience, dynamic scalability, and extendibility to grow functionality as business needs evolve.

3-40%

EH&S incident reduction2-6%

Increased availability for gas and steam power plants2-6%

Reduction in reactive maintenance2-6%

Inventory cost reduction

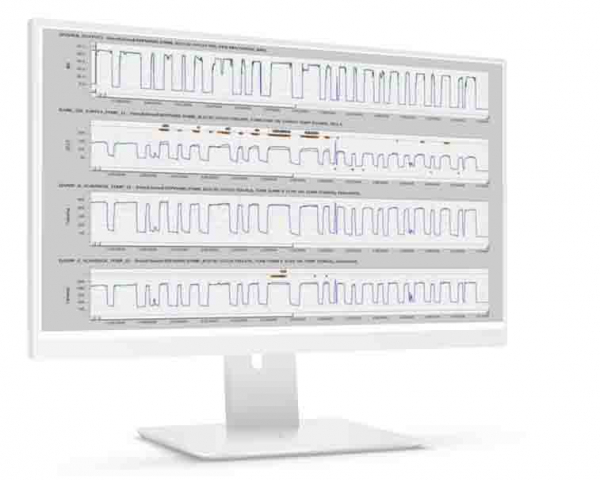

GE SmartSignal provides the Digital Twin analytics, alerting, and analysis tools at the core of the APM solution. Unique predictive, diagnostic, and forecasting analytics work together to detect emerging issues, identify the cause, and indicate the required timeframe for action. SmartSignal data, alerts, and results are an integrated component of APM Health dashboards, APM Reliability, and other APM functions.

APM Health Manager provides a comprehensive view of asset health, featuring drill-down views of performance data, alerts, performance KPIs and more. Dashboards are powered by APM’s robust OT/IT data collection, EAM/CMMS integration, and policy rules engine. For manual data collection, APM Health includes APM Rounds – a versatile mobile application that guides and digitizes data collection and other O&M activities.

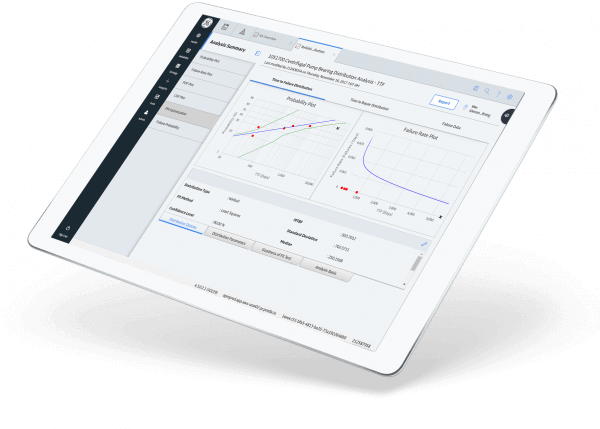

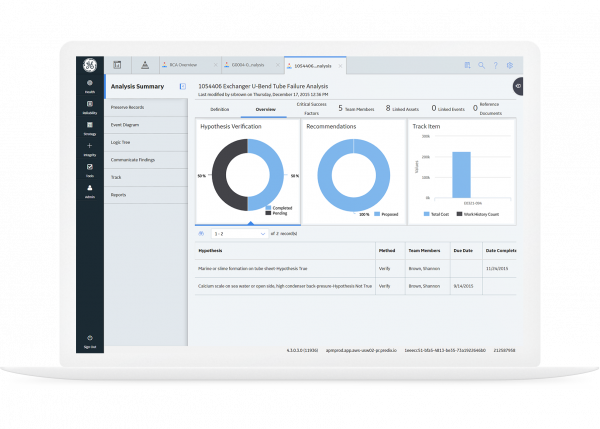

Featuring rich Digital Twin blueprints and SmartSignal machine learning analytics, APM Reliability provides visibility and analysis of asset performance, trends, and predictive alerts. With built-in workflows for root-cause analysis, reliability management, and collaboration. APM Reliability allows operators to proactively detect and correct emerging issues while running long-term performance improvements.

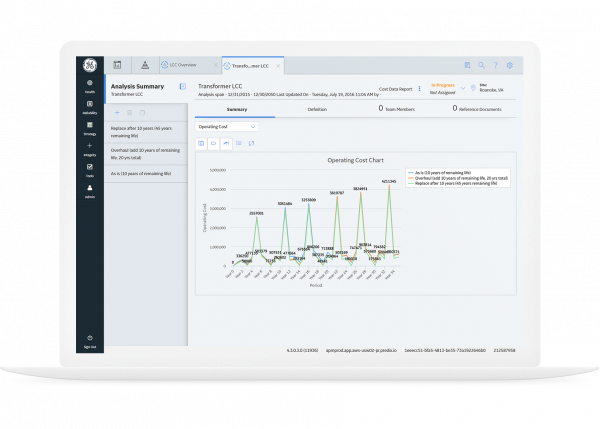

With features including criticality and risk analysis, lifecycle cost analysis, EAM integration, RCM, and FMEA, APM Asset & Maintenance Optimization (AMO) allows you to develop optimal O&M strategies with full regard to availability, reliability, risk, and cost factors. By consolidating pre-built GE industry expertise with the rich functionality of the standard APM Strategy module, AMO can help you to meet your operational and business goals rapidly.

APM is intended to operate standard power generation processes from O&M workflows to strategic planning. These functions and workflows feature-rich pre-built content from decades of experience in both APM software and managing over 40% of the world’s electricity generation. Pre-built content for 100’s of common assets includes