SmartSignal helps detect, diagnose, forecast, and prevent emerging equipment failures. Powered by unique Digital Twin analytics, SmartSignal’s early detection and time-to-action forecasting drive improved reliability with maximum O&M efficiency.

SmartSignal is available as on-premises software or cloud subscription and as an integrated component of the GE Digital APM application suite.

“The time-to-action analytic adds a new dimension to GE Digital’s APM capabilities... Adding a time factor to problem diagnosis provides an important benefit toward optimizing maintenance activities while avoiding downtime.”

Provide early and accurate detection of emerging issues for 100’s of common industrial assets

Leverage GE industrial knowledge to indicate probable cause and suggest possible maintenance actions

Forecasts actual malfunction time-frame to allow accurate maintenance prioritization and scheduling

Provides the complete toolset for end-to-end predictive maintenance activities

Out-of-the-box Digital Twin blueprints are rapidly prepared and deployed per asset

Monitors sensor status and current failure mode coverage per asset to ensure optimal results

Effective predictive maintenance centers are based on advanced analytics, and GE Digital is a leader in machine learning analytics for a wide array of equipment classes across OEM providers.

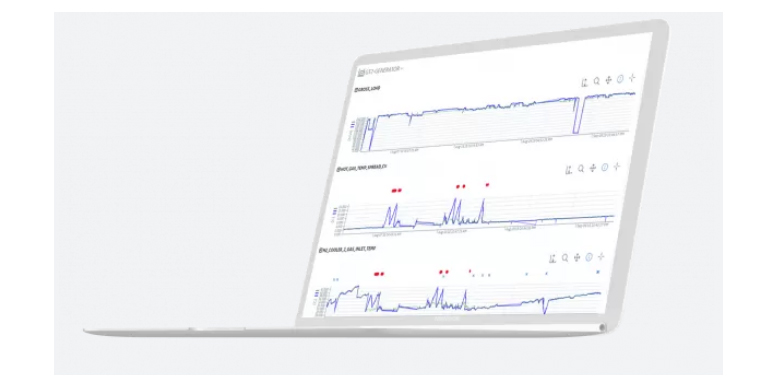

SmartSignal Digital Twins provide automated surveillance to discover developing issues, diagnostic guidance for causal analysis and actions, and time-to-action forecasting intelligence to ensure remediation is scheduled before any failure.

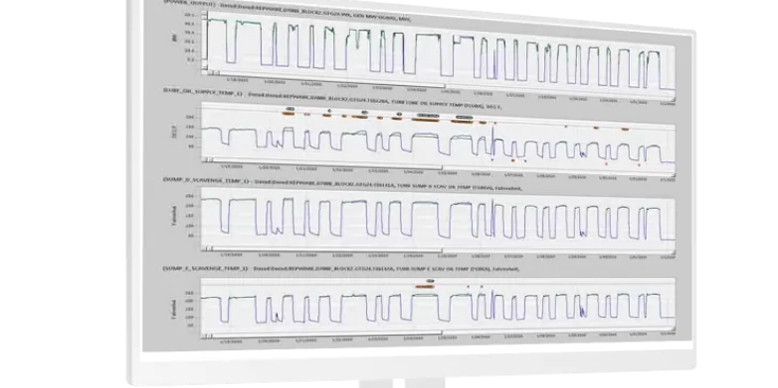

SmartSignal’s rich visualization, analysis, and case management tools coupled with analytics intelligence provide a fully closed-loop solution for predictive maintenance and asset reliability management.

Reliability and maintenance engineers can examine alerts, perform root cause analysis, determine immediate and long-term maintenance strategies, and track ultimate success.

SmartSignal Digital Twins are built on years of GE expertise in industrial manufacturing, operations, service, and software. The growing Digital Twin catalog covers more than 330 common industrial assets, providing predictive, diagnostic, and forecasting analytics.

Standard analytic blueprints for rotating, fixed, electrical, and mobile equipment classes are rapidly prepared to create accurate machine learning analytics tailored for each monitored asset. These analytics leverage a wealth of asset class intelligence including known failure modes, instrumentation inputs, operating context, engineering specifications, and GE subject matter expertise.

GE management of your SmartSignal solution provides 24x7 asset monitoring, issue triage and notification, remediation guidance, analytics management, and strategy consulting – available with software purchase/subscription or as a turn-key outsourced offering.

The GE Industrial Managed Services organization monitors thousands of assets around the globe and has saved our customers over $1.6 Billion over its history. Our full spectrum of expert services can guide and facilitate your overall reliability program and any digital initiative.

SmartSignal is also available as an integrated pillar of GE Digital APM, combining powerful analytics within a comprehensive asset and O&M management solution. The close integration with APM Reliability and general APM capabilities allow SmartSignal data and results to be a core component of health dashboards and reports, reliability management activities, strategic planning, and other APM functions.