With APM Reliability, part of the GE Digital's Asset Performance Management, the asset-intensive organizations can leverage advanced predictive diagnostics to interpret data, and detect and diagnose asset problems before they occur. Thus allowing companies to schedule downtime and control costs on their own terms.

APM Reliability is designed to work across all assets (fixed, rotating, and non-rotating), all equipment types and manufacturers (GE and non-GE), and all industries—across the plant and the enterprise.

Path to reliable operations in a volatile market: Finding hidden value in your production asset data

Everything You Need to Know about Asset Performance Management Steve Deskevich

A Reliability Engineer's Tale: 7,500 Motors and a Clipboard GE Digital

Collaborate across functional teams to make better operational and maintenance decisions.

Measure the effectiveness of asset strategies to know when corrections are warranted.

Develop and retain best practices from an ever-changing workforce to continuously improve decision-making.

Digital twin blueprints enable the analyst to anticipate or identify the collapse of an asset with a longer lead time to improve reliability and performance by modeling the asset’s expected versus observed states. The analyst can leverage structured time-series data and unstructured data, including process parameters and condition alerts, in the context of the assigned maintenance strategy and actual maintenance performed. It can also compare operating conditions and performance with other similar assets.

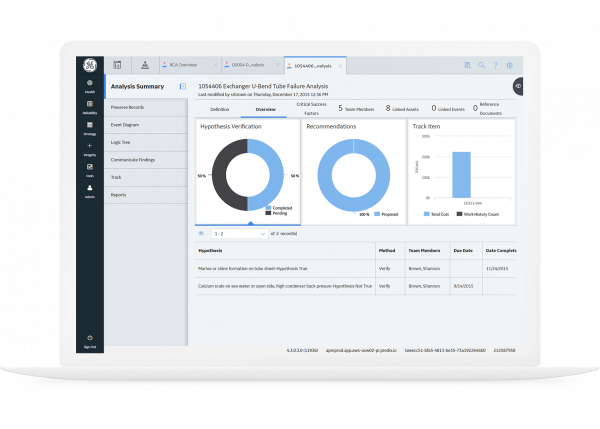

RCA helps equipment owners have a better understanding and analysis of the underlying causes of failure and then captures and institutionalizes that information to help prevent future occurrences.

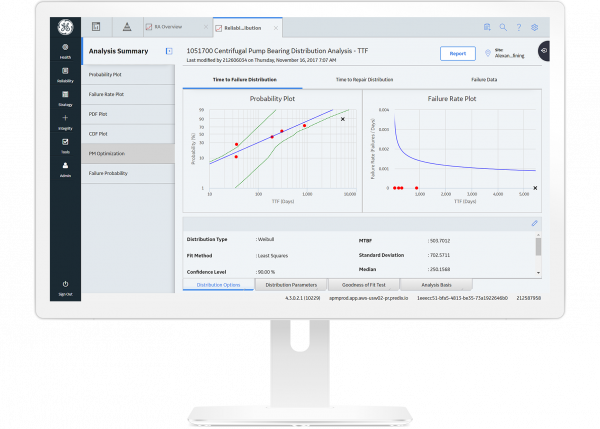

Reliability analysis provides a comprehensive set of analytical tools to help better understand the causes of asset breakdown patterns and the true cost of failure.

Understanding the historical costs, failure frequencies, and trends of production assets is a critical component of any asset performance management program.

2-6 %

Increased availability2-6 %

Increased availability2-6 %

Increased availability